The project

Located near the heart of Europe’s chemical and automotive industries, the Zinnwald Lithium project benefits from Saxony’s history of mining activity and from its extensive existing infrastructure. Sustainability and efficiency considerations are built into every step of our process.

The project is situated on one of Europe’s largest lithium resources: an ore body that straddles the German-Czech border under the villages of Zinnwald and Cinovec. The area gave its name to Zinnwaldite, a type of lithium-bearing ore first discovered in 1845.

Exploiting the brownfields advantage

The Zinnwald Lithium project will be an unusual mix of old and new infrastructure as we repurpose and “upcycle” elements of the pre-existing Altenberg tin mine.

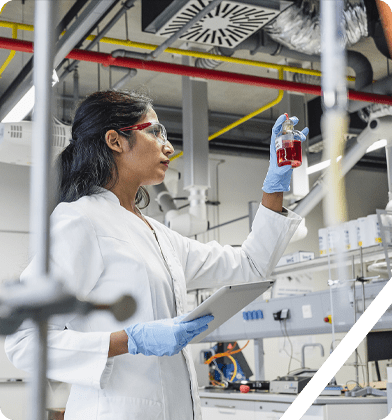

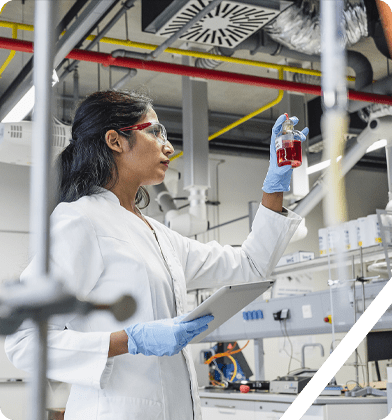

Extensive work has gone into designing the most efficient and cost-effective processing route for producing lithium hydroxide from ore. We use non-toxic additives and our low-waste process is designed to ensure that as much as possible of what comes out can be used commercially.

Why

Zinnwald Lithium?

Zinnwald Lithium is seeking to build a world-leading, highly economic business that will uphold high environmental standards. Find out more about the investment case.